"Bluecold" (Bluecold)

"Bluecold" (Bluecold)

06/16/2015 at 11:06 • Filed to: None

1

1

11

11

"Bluecold" (Bluecold)

"Bluecold" (Bluecold)

06/16/2015 at 11:06 • Filed to: None |  1 1

|  11 11 |

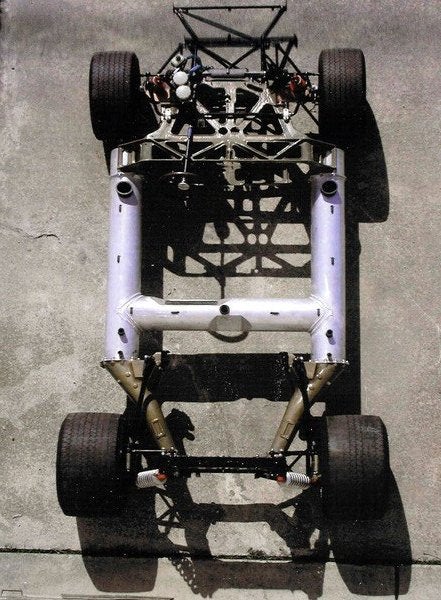

The front bit is a single magnesium casting.

The rest are thick aluminium tubes. I’d bet a lot of dollars on this being better at side impact testing than a Volvo. Front impact will probably result in a burning magnesium front subframe though. Rear impact will also result in a fire because that’s where the engine is located.

Props for correctly identifying the car without google image lookup.

EDIT, some more photos of the Alfa Tipo 33 Stradale with the drivetrain out, kindly supplied by

!!! UNKNOWN CONTENT TYPE !!!

Smallbear wants a modern Syclone, local Maple Leafs spammer

> Bluecold

Smallbear wants a modern Syclone, local Maple Leafs spammer

> Bluecold

06/16/2015 at 11:09 |

|

Body on frame is always done right.

Bluecold

> Smallbear wants a modern Syclone, local Maple Leafs spammer

Bluecold

> Smallbear wants a modern Syclone, local Maple Leafs spammer

06/16/2015 at 11:15 |

|

If you don’t care about flexural stiffness or weight, then you’re right. Most frames are thin and narrow. You need big tubes as far apart as possible to get stiffness.

Smallbear wants a modern Syclone, local Maple Leafs spammer

> Bluecold

Smallbear wants a modern Syclone, local Maple Leafs spammer

> Bluecold

06/16/2015 at 11:18 |

|

Body on frame is always done right.

904 GTS

> Smallbear wants a modern Syclone, local Maple Leafs spammer

904 GTS

> Smallbear wants a modern Syclone, local Maple Leafs spammer

06/16/2015 at 11:19 |

|

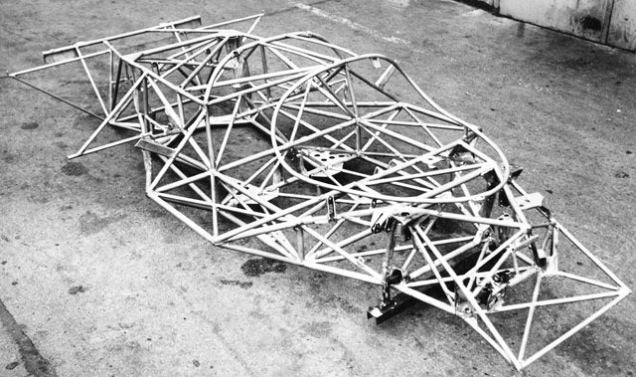

Alfa Romeo T33 Stradale chassis above. Interestingly, those huge tubes on both side were also fuel tanks. Here, all dressed up. One of THE MOST BEAUTIFUL cars ever!

Smallbear wants a modern Syclone, local Maple Leafs spammer

> 904 GTS

Smallbear wants a modern Syclone, local Maple Leafs spammer

> 904 GTS

06/16/2015 at 11:21 |

|

Come forth from the Grey!

I think you replied to the wrong place though.

Smallbear wants a modern Syclone, local Maple Leafs spammer

> Bluecold

Smallbear wants a modern Syclone, local Maple Leafs spammer

> Bluecold

06/16/2015 at 11:27 |

|

904 GTS replied to me by mistake. Are they right?

http://oppositelock.kinja.com/alfa-romeo-t33…

kanadanmajava1

> Bluecold

kanadanmajava1

> Bluecold

06/16/2015 at 11:31 |

|

Without any googling I’ll say Alfa-Romeo Tipo 33.

Bluecold

> Smallbear wants a modern Syclone, local Maple Leafs spammer

Bluecold

> Smallbear wants a modern Syclone, local Maple Leafs spammer

06/16/2015 at 11:38 |

|

Tipo 33 Stradale (and other Tipo 33’s, but not all afaik) is definitely correct. Brilliant car, inside and out.

904 GTS

> Bluecold

904 GTS

> Bluecold

06/16/2015 at 11:48 |

|

Many triangulated smaller, lighter tubes as required = STIFFNESS. Here a PORSCHE 917 Coupé chassis for you to study.

Bluecold

> 904 GTS

Bluecold

> 904 GTS

06/16/2015 at 12:03 |

|

Thanks for that great picture as well!

To me that is more a ‘tube frame’ than a body on a flat frame. The little tube approach works as well, but is more a ‘stepping stone’ to a full monocoque with a load-bearing skin, where the Alfa’s frame was a way to get some cross sectional area in the frame tubes. Swept area is the main determiner of the stiffness of a tube. Two very different schools of thought.

904 GTS

> Bluecold

904 GTS

> Bluecold

06/16/2015 at 14:31 |

|

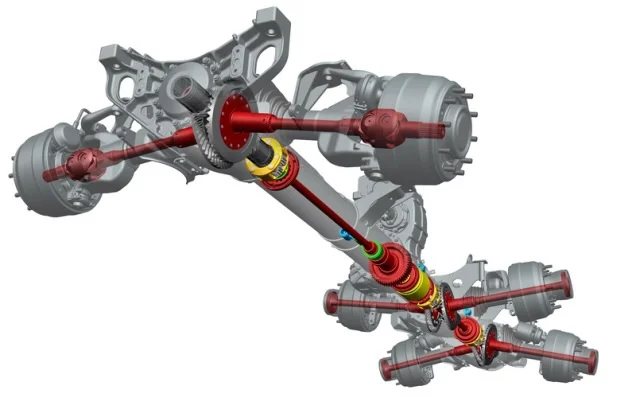

Here is an interesting solution to BODY on FRAME from Engineer Ledwinka of TATRA.

Ledwinka was a contemporary to Ferdinand Porsche.

Porsche adopted the back bone with an integral platform as his basic frame, which he very successfully used in the original VW. Variety of body types were than bolted onto that back bone platform.

Ledwinka, on the other hand, decided on the above tube and fange approach for his basic frame. Thus, in a car application of that idea, there was a large diameter, long tube in the center (also carrying the drive shaft), with flanges on both ends. Onto the back flange was bolted the swing-axle rear end. In front, since first TATRA road going cars were front engined, an engine with transmission was bolted onto the front flange.

The tube had thus became the frame onto which brackets were fastened for the body.

The above drawing is a chassis from a TATRA all wheel drive truck.

It too has the very large diameter tubes with flanges as its base for a chassis. In the center is the transfer case. From it a tube runs forward, with a drive shaft in it, to power the front differential and front drive axles. To the rear of that middle transfer case, another tube runs to the first rear dif. To it is attached, all on flanges, the second rear dif. Since TATRA trucks use V12 air cooled engines over the front dif, so in the front structure above it, are the mounting points for the engine cradle. The engine has a gear box behind it, which again with flange attaches to the upper part of the transfer case to power it all.

Being made from tubes and flanges, that chassis wheel base is therefore very easy to modify.

If a short dump truck was no longer needed and a long-bed truck desired instead, that could be very easily accomplished by removing the dump truck’s bucket, replacing the short rear going tube from the transfer case with an appropriate lenght one for the much longer bed truck one, than together with wiring, air and hydraulic lines all could be accomplished in no time flat.

Beside the engine cradle, there are other attachments to those tubes to put various bodies on that most interesting chassis.